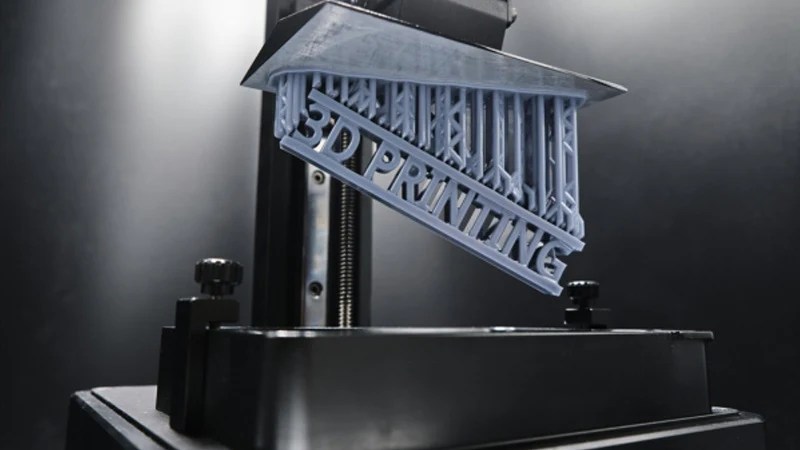

Traditional 3D printers such as FDM, resin, and SLS printers manufacture objects by printing materials layer by layer to achieve the shape of the final product. This process, known as additive manufacturing, despite having several advantages compared to other manufacturing techniques, still has several limitations. Regions of the model that hang in the air need a base to be printed upon, which is why temporary support structures are imperative for most 3D prints. These structures lead to a lot of waste material, and when printing with more rigid materials, support structures are difficult to remove. Therefore, an engineer must keep these limitations in mind when designing, and for many parts, 3D printing them is not possible.

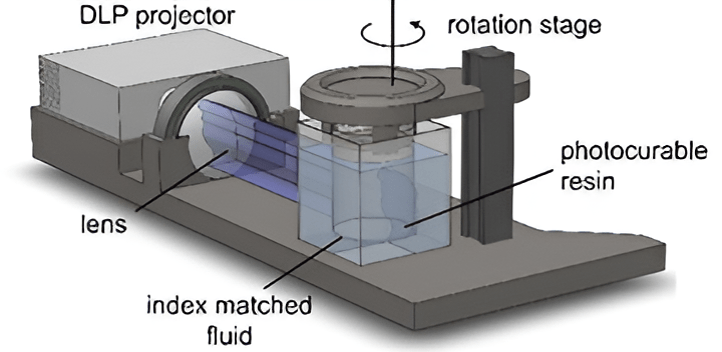

Invented in 2016 by researchers at the University of California, Berkeley, Computed Axial Lithography (CAL) is a 3D printing technique that solves many of these issues. Instead of being an additive manufacturing technique, this technology creates the entire volume of the print simultaneously and is thus known as volumetric printing.

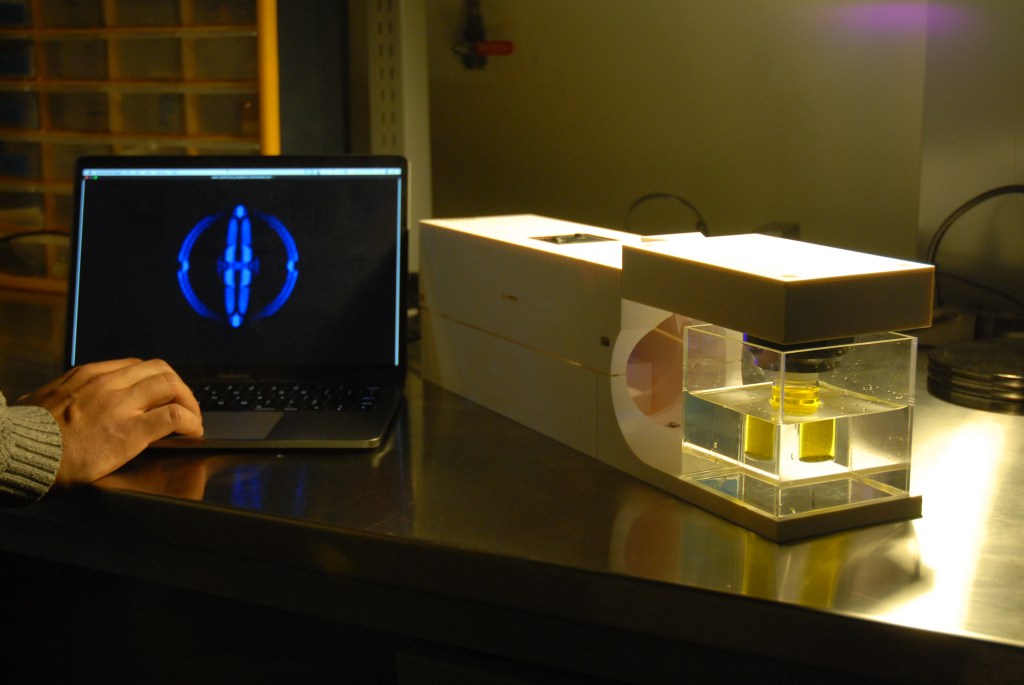

The first step is to convert the 3D model into a form suitable for printing. Instead of slicers, which are used to create the instructions for FDM, resin, and other traditional printers, a projection software is used to take computed tomography (CT) scans of the model. These scans are then projected onto a photopolymer resin volume, which solidifies in the presence of blue light (4-5 nm wavelength). This volume, which is shaped like a vial, is placed in a cuboidal glass container filled with a fluid that has the same refractive index as the glass. This is done because the vial’s round surface area would cause the blue light to reflect and refract, creating undesirable geometries. The vial and the photopolymer resin inside rotate, and the projection software projects frames at the speed at which the vial rotates, activating the photo initiator in the resin, which causes the monomer molecules in the resin to chemically bond, forming the 3D model.

Not only is this process much more efficient, but it is also more sustainable

- Limited material waste: Photopolymer resins are used, which only solidify when exposed to light. Therefore, only the resin that is part of the 3D model is solidified, resulting in minimal material waste.

- Reduced energy consumption: Instead of melting filaments or using high-temperature lasers to melt material into layers, CAL uses light-based curing, which consumes much less energy, making it a more efficient process.

- Ability to print more complex designs: Since the entire volume of the object is synthesized simultaneously, much more complex designs can be made without extensive post-processing.

- Overprinting: One of the most fascinating use cases for this technology is the ability to print models over already existing objects, such as an outer shell over a physical earphone module. This can be used to create various integrated assemblies.

In conclusion, Computed Axial Lithography is a breakthrough in 3D printing and manufacturing technology. By using light projections onto photopolymer resin, this technique is not only incredibly fast but also much more sustainable. In the future, greater precision and accuracy can be achieved, along with the capability to print using different biodegradable materials. The applications are endless.